Laser Cutting and engraving services

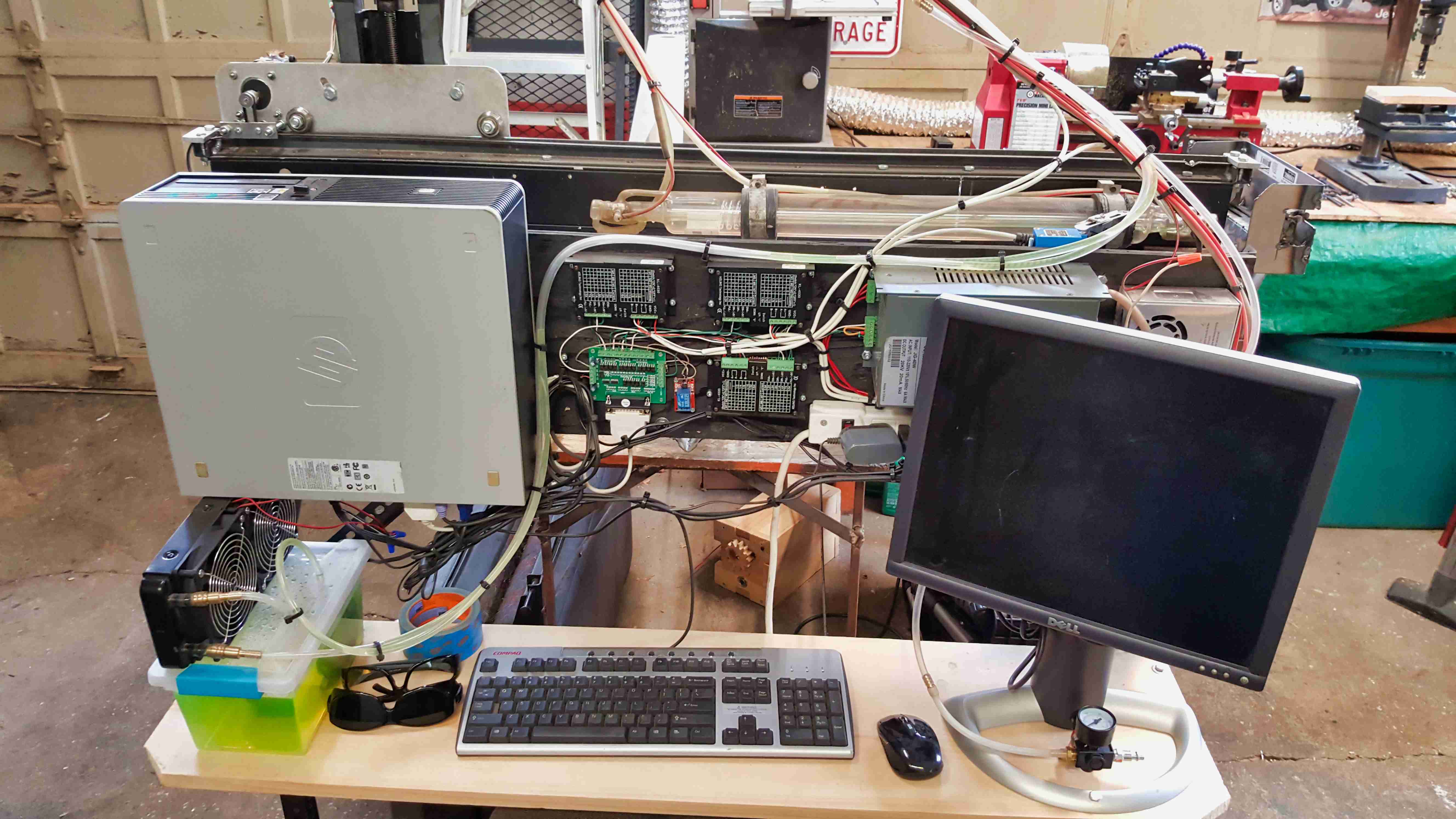

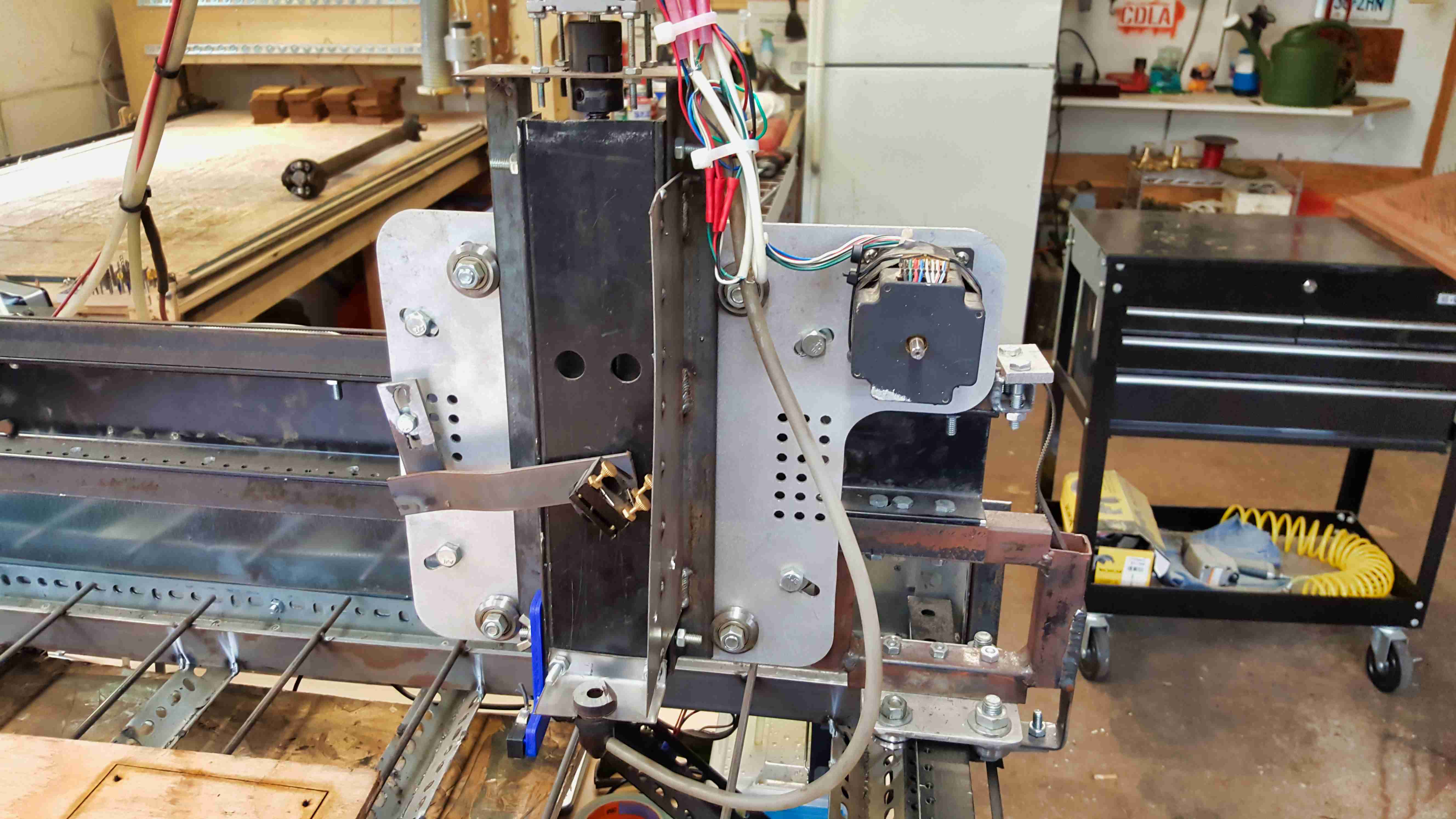

A while back CDLA got a laser cutter. Then it spontaneously caught fire. Then we didn't have a laser cutter for a while, but the laser and driver were still good. After some thought, and instead of simply buying a new one, it was decided that one should be built. After all the work area of the first unit was no more than 8"x12" which is tiny, and we were constantly running out of space. The new one has a work surface measuring 25" x 32" and runs linuxCNC, the same software as the mill, which lends itself to more intricate projects as the software is more configurable. This unit was built for under $400, and while it doesn't look pretty by any stretch of the imagination, it runs very well. The motors were off an old CNC machine, capable of 276 OZ/In. of torque, and are set at 1/16 microstepping for high precision applications. The gantry ways are from a junk yard and appear to be an old server rack. The carriage was CNC cut to ensure accuracy. The tool tips are replacable, and a plasma tip holder can be installed to quickly and easily convert the laser cutter into a CNC plasma cutter for work up to 3/8 thick. This is why the bed is metal, and the spoil board is not affixed. We are set up for medium metal cutting runs, and small to large laser runs. Machine run time is not billed on single production runs.

If you have something you would like made please feel free to send us an email at clayludwig@Gmail.com.