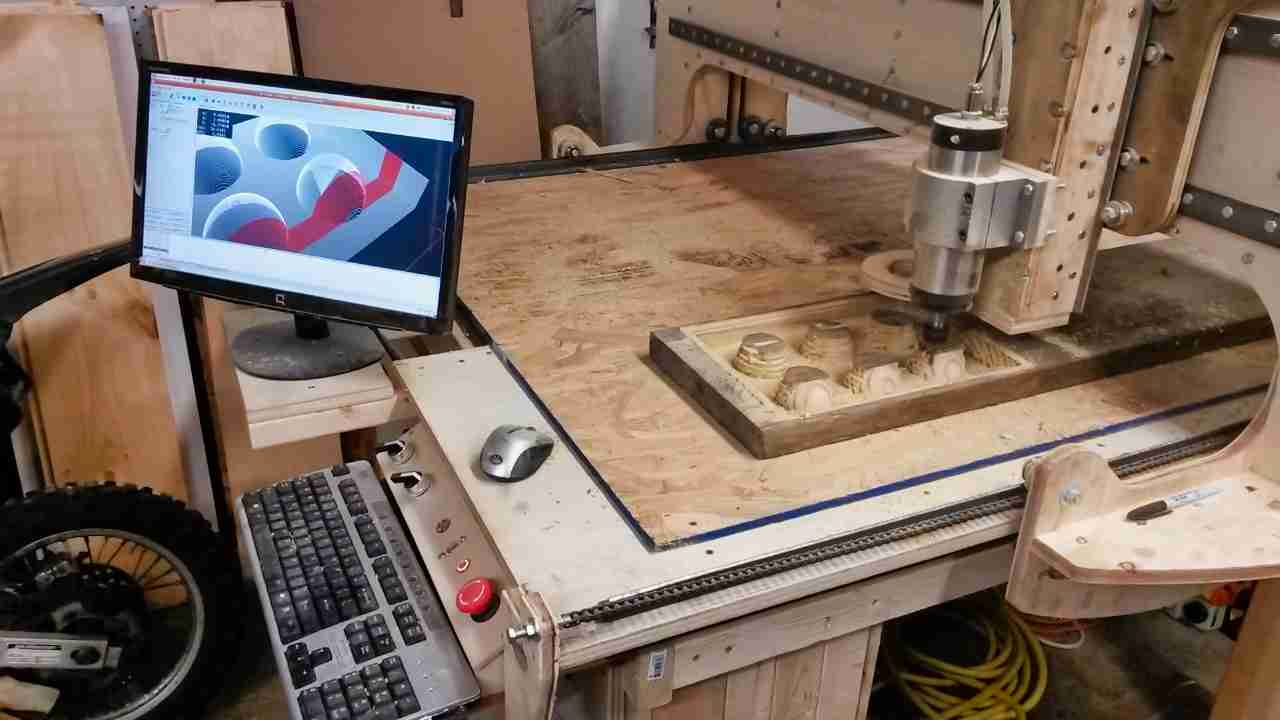

The New Mill and Shop Setup

This mill was new as of around December or 2015, and man was it an upgrade. The last one was all MDF with leadscrew drives. It was perhaps a tad more precise than this one, but was super slow, and was falling apart because, well, it was MDF. This new guy took me 2 months or so, but has almost all the trimmings a good machinist would want. Maybe without an A axis, but all the same. 600 IPM max jog, 48" X 78" area, adjustable speed three phase water cooled spindle, and a taller gantry. Thankfully with all these upgrades we can cut some softer metals. True, it takes a while because I need to make a few passes, but it's very do-able. I also spent a lot of time making sure everything was well assembled, and all the cabling was clean; that was also a huge issue with the last one. As for the rest of the shop, it changed with the machine. I got a better understanding of what I wanted to do and what CDLA was capable of as a company, and geared new equipment towards those goals. With a mig welder, grinder, lathe, and plasma cutter we're much better at metalwork. And because I started a whole ton of new projects I realized I needed more table space. So, more tables were added. Obviously.

Projects got more complex, from signs and enclosures to projects that required the development of custom PCBs and specialized code. Throughout my time working at the UCONN Marine Biotech Lab and the University of New Hampshire, projects become more advanced and required more development. Thus, better tools and equipment were added to the inventory. And that being said, I love to make new things, and see what we are good at, and furthermore what people want. It's also very nice to get others involved in what we do. If you have an idea, or just want to swing by and make something with us, our mill is your mill. Shoot us an email.